2021.03.10

Innovative robotic inspection technology eliminates dependence on human hands: Laser hammering system makes strides toward implementation

Technology & Research

Based on a business alliance with QST-certified RIKEN Venture PhotonLabo Co., Ltd. and the results of joint research with the National Institutes for Quantum and Radiological Science and Technology (QST), CTI Engineering Co., Ltd. (Managing Director and Chief Executive Officer: Tetsumi Nakamura) has become the first in Japan to use a "laser hammering system," which replaces and quantifies the results of manual hammering inspections performed during the periodic inspection of road tunnels, to assist in road tunnel assessment.

Laser hammering inspection of road tunnel concrete joints

1. Overview

CTI Engineering Co., Ltd. (Headquarters: Chuo-ku, Tokyo; Managing Director and Chief Executive Officer: Tetsumi Nakamura; hereafter "CTIE") has concluded a business alliance agreement with PhotonLabo Co., Ltd. (Headquarters: Chuo-ku, Tokyo; CEO: Shigeru Kogure; hereafter "Photon-Labo"), and through joint research with the National Institutes for Quantum and Radiological Science and Technology (Headquarters: Chiba City, Chiba; President: Toshio Hirano; hereafter "QST"), has used a laser hammering system to assist in the assessment of a tunnel for the first time in Japan. The laser hammering system is a type of robotic inspection technology that assists inspection engineers during the periodic inspection of road tunnels.

2. Research background

Conventionally, during maintenance and preservation work on tunnels and other structures, inspections are performed by specialized engineers using visual inspection and manual hammering inspection methods, which require considerable time and effort and pose risks such as falling during work. In addition, there have been concerns about a future shortage of engineers capable of performing hammering inspections, as well as a strong need for the implementation of remote and non-contact measurement technologies to supplement and support inspection work. In order to meet these needs, CTIE and Photon-Labo have been preparing for the full-scale implementation of "laser hammering technology," which is an outcome of research under the Strategic Innovation Program (SIP) led by the Cabinet Office.

3. Laser hammering system implemented for the first time in Japan

This time, a laser hammering system was used to assist the measurement and assessment of joints in tunnel concrete lining, where it is generally known that many deformations occur, based on the results of the "Research on the Advancement of Concrete Assessment Using Laser-Induced Vibration Measurement Technology (Laser Hammering)" project conducted through collaboration with QST. The laser hammering system uses two types of lasers--an "impact laser" that vibrates the concrete lining in place of a hammer and a "detection laser" that measures the vibrations in place of the human ear--to enable hammering inspections to be conducted remotely and digitally. In this study, we used the laser hammering system to measure vibrations in areas suspected of harboring internal damage which were detected through manual hammering, recorded the results as quantitative data, and compared them with the measurement data from concrete specimens that simulated the damage, in order to improve the quality of internal damage assessments.

4. Benefits of the technology

Taking measurements with the laser hammering system ensures the fundamental safety of inspectors by eliminating the need for them to work at dangerous heights in order to perform hammering inspections, and it also eliminates differences in inspection results based on individual skill levels. Furthermore, using this system can improve the quality of concrete damage assessments and leave a quantitative record of tunnel health, which can be compared with records from prior years to assess the degree of deterioration that may lead to concrete collapse. The continuous acquisition of such records will make it possible to quantitatively identify internal damage and other changes over time, as well as to monitor the rate of deterioration, contributing to the increased efficiency and sophistication of inspection and maintenance management activities.

5. Future outlook

The laser hammering system was developed with a focus on tunnel concrete lining, but we will proceed to apply it to various other infrastructures and continue the development of safe and reliable inspection robots that eliminate reliance on human hands.

◆ Features

(1) Performs inspections as good as or better than manual hammering

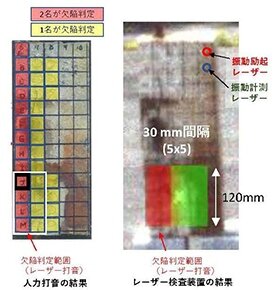

During a joint research project with QST ("Research on the Advancement of Concrete Assessment Using Laser-Induced Vibration Measurement Technology (Laser Hammering)"), we have confirmed that the laser hammering system can detect abnormalities in areas that were judged to be "defective" by several experienced inspection engineers.

■ Comparison of manual hammering and the laser hammering system

Testing the system in comparison to manual hammering using a concrete specimen

Results provided by the laser hammering system

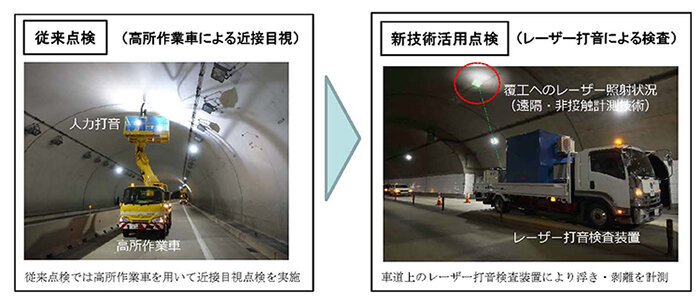

(2) Does not require an aerial work platform truck

The laser hammering system can measure vibrations from up to 10 meters away. A laser hammering system can perform hammering on the top concrete lining of a tunnel from the road below.

■ Taking measurements in a tunnel using the laser hammering system

Taking measurements in a tunnel