2024.08.08

CTI Engineering Co., Ltd. developed an earthquake-resistant reinforcement design support system that improves the efficiency and quality of earthquake-resistant reinforcement design.

Technology & Research

Earthquake-resistant reinforcement design for bridges required a lot of manual work and therefore was prone to human errors. CTI Engineering developed an earthquake-resistant reinforcement design support system to prevent the errors.

1. Background

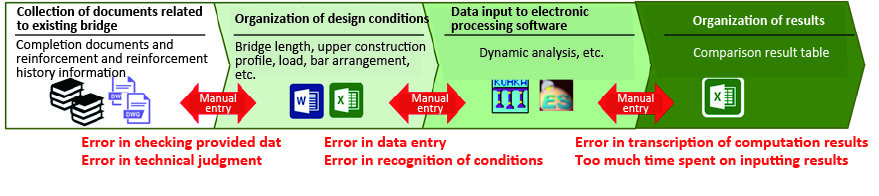

Earthquake-resistant reinforcement design for bridges inherently has the risk of applying incorrect conditions and entering incorrect design conditions by hand due to the compromised readability of the provided documents related to the existing bridge. In order to control such risks, it is essential to correctly understand the documents and accurately apply conditions for design calculation. Not only can a single mistake cost immense time and money for correction, but it can also have an enormous impact on the society as a whole. Taking measures to eradicate such mistakes from the earthquake-resistant reinforcement design for bridges is now a crucial need.

To address this issue, CTI Engineering developed the earthquake-resistant reinforcement design support system. This system automates and simplifies the consistency check of design conditions and input conditions, as well as the validity check of design load, and quickly provides design deliverables without any error while ensuring quality. The purpose of this system is to contribute to efficient infrastructure maintenance and management.

Fig. 1 Areas that are prone to mistakes in earthquake-resistant reinforcement design

2. Features and details of the earthquake-resistant reinforcement design support system

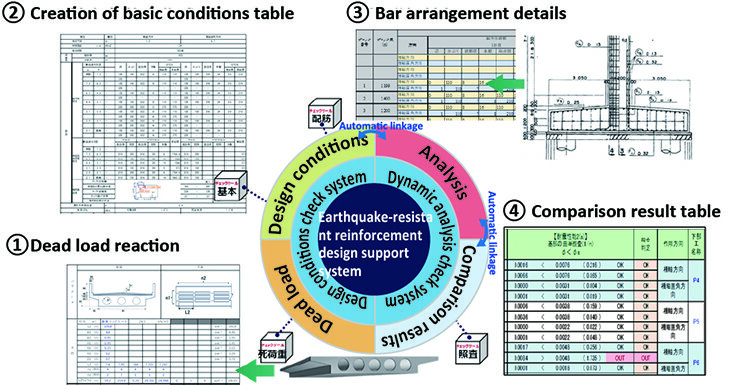

For the earthquake-resistant reinforcement design support system (see Fig. 2), we developed the following four tools to reduce errors, including those in transcriptions by hand, provide time for comparison and review by means of streamlining and automating the production process, and simplify third-party review.

(1) Dead load reaction check support tool

Dead load reaction is a core design condition in designing earthquake-resistant reinforcement. It is often extracted from reports and drawings created during construction design, and applying incorrect information can lead to a serious defect. This tool calculates the dead load reaction of particularly frequently used bridge types (plate girders and box girders of steel bridges, and hollow slabs, box girders, and T-girders of concrete bridges) from the profile of the upper construction, allowing users to check the validity of the extracted values.

(2) Basic conditions table creation support tool

This tool was developed with the aim to prevent errors in recognition and input of design conditions organization and electronic processing software. It automatically generates a design conditions table from bar arrangement information created using the (3) Bar arrangement details creation support tool, which is described later. The design conditions table is provided in a format that allows third parties to easily find mistakes.

(3) Bar arrangement details creation support tool

Bar arrangement information, including the diameters and numbers of steel reinforcement bars in the existing lower bridge structure and any changes in the cross-sections, can be complex and require much time for organization. Errors in transcription may also occur when entering values into electronic processing software. This tool ensures correct data entry by automatically converting bar arrangement information to the input format of the electronic processing software.

(4) Comparison result table creation support tool

Analyzing earthquake-resistant reinforcement design produces a massive calculation output, from which users manually enter the necessary information into the results table. Not only does this take a large amount of time, but it is prone to transcription errors. In response to this issue, we developed a tool that automatically outputs analysis results to a comparison result table. This shortens work time and improves accuracy.

Fig. 2 Features of the earthquake-resistant reinforcement design system

3. Future outlook

Through practical application, CTI Engineering will enhance and expand functionality by means of furthering versatility and automation, aiming to improve the production efficiency of earthquake-resistant reinforcement design. We will also convert analysis results to diagrams and graphs as part of our visualization efforts to facilitate the noticing of mistakes. We will contribute to society through providing a high-quality system for the development of safe infrastructure.