2023.05.30

Innovative robotic inspection technology eliminates dependence on human hands Demonstration experiment of a remote laser hammering inspection targeting a road bridge

Technology & Research

CTI Engineering Co., Ltd. has become the first company in Japan to demonstrate the use of its laser hammering inspection system--a measurement quantifying system that was developed as an alternative to conventional manual hammering inspections through joint research with the National Institutes for Quantum Science and Technology (QST), Tokai National Higher Education and Research System (Nagoya University), Keisokukensa Co., Ltd., and Photon-Labo Co., Ltd.--as diagnostic support technology for road bridges. As a result, the company successfully detected damage to a bridge floor slab from a ground position 30 meters away and diagonally beneath the bridge, thereby showing that the laser hammering inspection system can be used to remotely inspect road bridges.

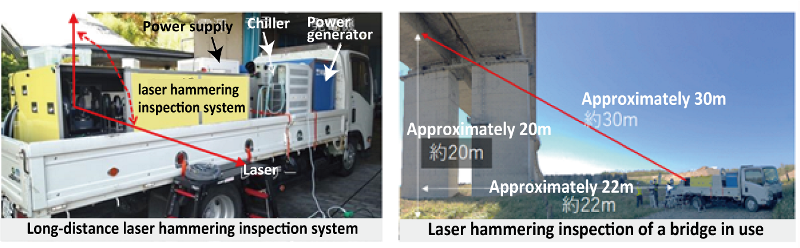

Photo 1: Laser hammering inspection of a road bridge

1. Background behind social implementation

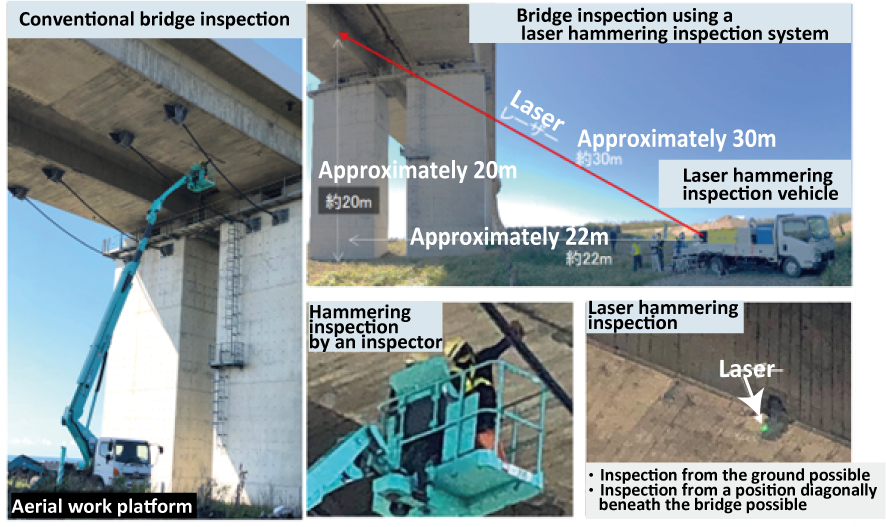

In the past, bridge hammering inspections have posed a challenge in terms of securing the safety of inspection engineers due to the need to do the inspections at inherently dangerous high positions. In addition, it has taken a long time to knock off materials that seemed like they were about to come off, and ensuring the precision of inspection records given the limited amount of inspection time has been a challenge. There have also been concerns regarding both variance in the inspection results of different inspection engineers as well as the shortage of such engineers. In response to such issues, there has been ongoing research of inspection supporting technology--including flying hammering robots developed as remote and non-contact measurement technology to complement and support inspection work--but such technology has been burdened by usage restrictions that include the inability to deal with wind, rain, and other inclement weather conditions. Therefore, CTI Engineering, QST, Nagoya University, Keisokukensa, and Photon-Labo developed diagnostic support technology that uses the laser hammering inspection system for road bridges.

2. Results of the demonstration experiment to test the use of the long-distance laser hammering inspection system on a road bridge

Laser hammering inspection systems enable the remote handling and digitization of hammering inspections by using a hammering laser, which acts as a hammer, and a measurement laser, which measures vibrations. Our goal was to take advantage of our accumulated experience and knowledge related to the social implementation of our inspection technology for road-tunnel lining concrete in order to demonstrate whether it is possible to use a laser hammering inspection system to detect damage to a bridge floor slab with the system positioned on the ground. However, the maximum inspection range for conventional laser hammering inspection systems when inspecting tunnels is only around 10 meters. Therefore, to apply such a system to the inspection of elevated bridges that are more than 10 meters in the air as well as especially wide bridges, we developed a new long-distance laser hammering inspection system that is portable and can be used to perform inspections from positions that are 20 or more meters diagonally away from the target bridge. As a result of our demonstration experiment, we confirmed that the new long-distance laser hammering inspection system can be used to detect defects in road bridges from a position up to 30 meters away with accuracy equivalent to conventional inspections manually performed by inspection engineers. We therefore successfully showed that a laser hammering inspection system positioned on the ground can be used to remotely inspect a road bridge.

3. Advantages of the technology

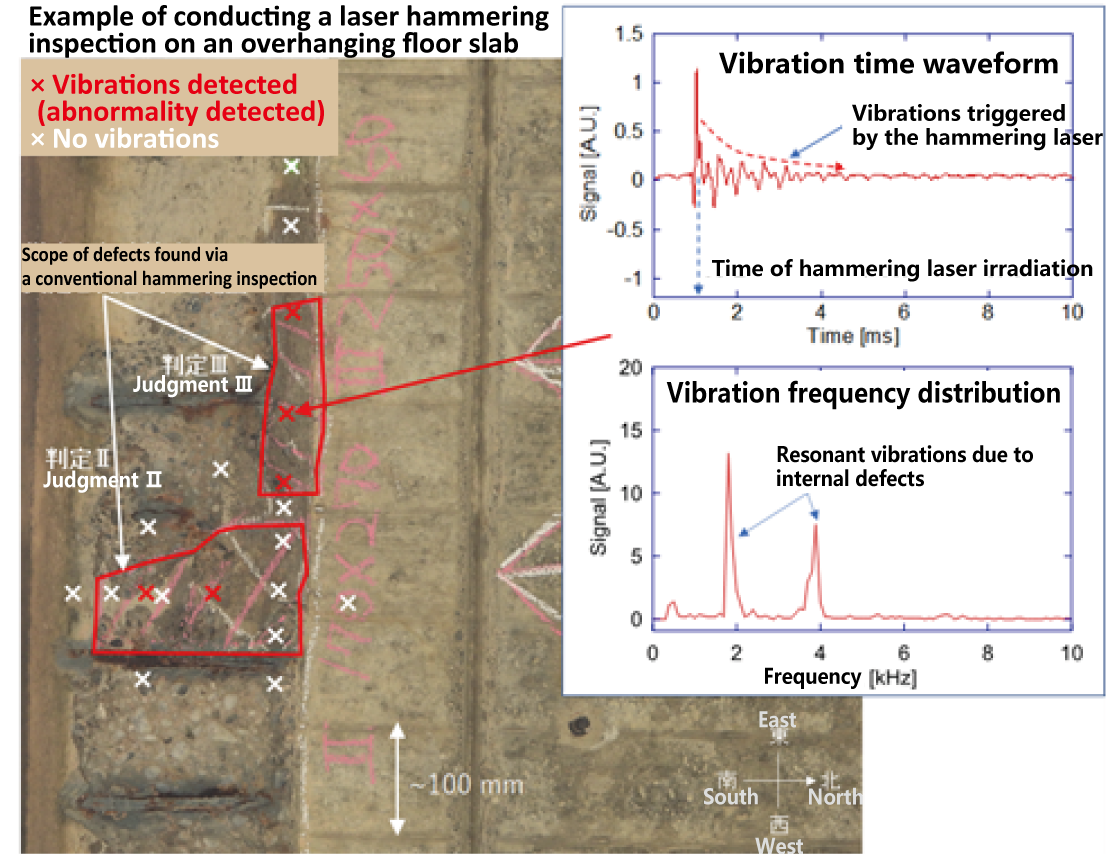

Because the measurement scope of the long-distance laser hammering inspection system increases in direct proportion to the distance (height) of the target with respect to the system's ground position, the system can increase the efficiency of measurement work while also ensuring the absolute safety of inspection engineers. In addition--because the inspection results include a continuous record of vibration value data--the system enables more efficient and sophisticated evaluation of the progress of lifting and peeling deterioration, which helps to judge the inspection priority, repair period, and other details more suitably.

4. Future prospects

By demonstrating the use of the long-distance laser hammering inspection system to inspect a road bridge, we confirmed that it is possible to inspect bridges up to 30 meters away. We will continue confirming the applicability of this system to long-distance bridges (by size and scale) and striving to improve both the diagnostic ability and efficiency of measurement work. In addition, by increasing the efficiency and sophistication of infrastructure-facility inspection and maintenance management activities, we will help improve user safety and prevent damage to third parties.

* This research was commissioned by the Chubu Regional Development Bureau of the Ministry of Land, Infrastructure, Transport and Tourism as part of its technical research and development of diagnostic technology that involves using a laser hammering inspection system to quantify the lifting and peeling of bridges, tunnels, and other road structures as data . This research is part of the Technical Research and Development Program of the New Committee on Advanced Road Technology, which was established by the Road Bureau of the Ministry of Land, Infrastructure, Transport and Tourism.

■ Features

(1) The safety of bridge inspection engineers can be ensured.

Photo 2: Comparison of a conventional inspection and an inspection using a laser hammering inspection system

(2) Bridge-floor-slab lifting and peeling can be measured as vibration value data.

Photo 3: Example results of using a laser hammering system to measure damage to a road bridge