- TOP

- Project Introduction

- Technology used for the first time in a dam managed by the MLIT

PROJECT INTRODUCTION

Technology used for the first time in a dam managed by the MLIT

| Location : | Bonji River, Akagawa River system (Tsuruoka City, Yamagata Prefecture) |

|---|---|

| Period : | 1978 – 2012 |

| Client : | Gassan Dam Management Office, Tohoku Regional Development Bureau, Ministry of Land, Infrastructure, Transport and Tourism (MLIT) |

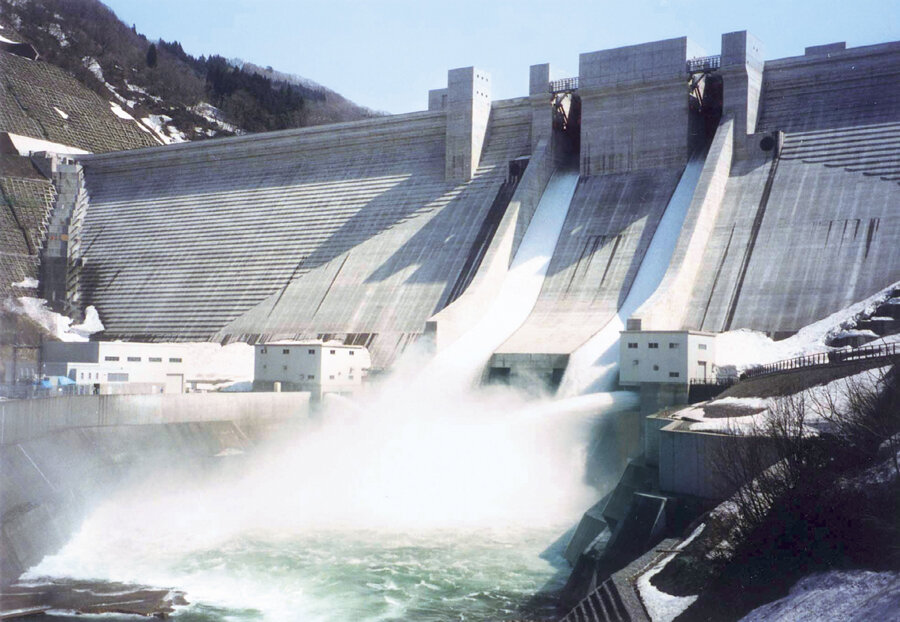

Gassan Dam Flood Control Project, Tsuruoka City

The Gassan Dam was constructed on the Bonji River of the Akagawa River system, a Class A river in Tsuruoka City, Yamagata Prefecture. Rivers in the Akagawa River system have a swift flow in the upper reaches, and a gentler flow in the lower reaches. Historically, they have been subject to repeated flooding in the middle and lower reaches. Improvements were made to rivers in the Akagawa River system in 1917 to counter these floods, but the flooding did not subside. Therefore, the Gassan Dam was planned as part of a subsequent flood control project. It is a 123-meter-high concrete gravity dam. The project was completed in 2001 with the aim of securing a stable water supply for the southern part of the Shonai region, including Tsuruoka City, which at that time used groundwater as its water source. It was also intended to control floods, maintain a regular river flow, and generate power.

The name of the lake formed by the dam is Asahi Gassan Lake. The Goddess of the Moon by Yutaka Kato, a sculptor from Shizuoka City, watches over the Gassan Dam from the Asahi Gassan Lake Observation Deck, where visitors can enjoy a panoramic view of the lake.

Visitors are allowed to tour the inside of the dam, including the inspection gallery. Those who wish to join a tour should apply at the Gassan Dam Management Office. The Gassan Dam Regional Disaster Prevention Center, located on the south side of the dam, also has an exhibit that introduces the Gassan Dam’s flood prevention function.

CTI Engineering actively used precast formwork in the design of the main body of the dam. In the construction plan and design of the facility, we proposed the use of the Roller Compacted Dam (RCD) method, a streamlined construction method for the placing of concrete for the dam structure, as well as a belt conveyor system to transport the concrete. This system was adopted for the first time in a dam directly managed by the MLIT. Until 2012, after the transition from construction to management, we were engaged as a “dam doctor” to assess the stability of dam through various dam behaviors, checking the seismographs, plumb lines, pumping pressure, leakage volume, displacement, distortion, and other factors indispensable for the management of the dam.